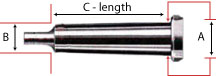

Morse Taper Shank Sizes

All

common woodworker's lathes and drill presses use a tapered

spindle for mounting your tooling. They are designed for a

male ended, slightly tapered shank that fits into the machine's

hollow housing. The action of the tooling forces the collet

farther into the housing, increasing the surface pressure

between the two metal plates and the resulting friction prevents

slippage. The design provides accurate centering and quick

installaton of drill chuck arbors and lathe centers. All

common woodworker's lathes and drill presses use a tapered

spindle for mounting your tooling. They are designed for a

male ended, slightly tapered shank that fits into the machine's

hollow housing. The action of the tooling forces the collet

farther into the housing, increasing the surface pressure

between the two metal plates and the resulting friction prevents

slippage. The design provides accurate centering and quick

installaton of drill chuck arbors and lathe centers.

In order to simplify the fitting of these two pieces a number

of standards were developed and adopted in the industry, the

most well know being the "Morse Taper" (MT) developed

in the late 1800's.

There are 8 sizes ranging from MT-0 to MT-7, each with a

given size as outlined in the table below:

| |

A

|

B

|

C- length

|

| 1 morse taper |

0.4750" 12.065mm |

0.3690" 9.373mm |

2.13" 54.10mm |

| 2 morse taper |

0.7000" 17.780mm |

0.5720" 14.529mm |

2.56" 65.02mm |

| 3 morse taper |

0.9380" 23.825mm |

0.7780" 19.761mm |

3.19" 81.06mm |

| 4 morse taper |

1.2310" 31.267mm |

1.0200" 25.908mm |

4.06" 103.12mm |

| 5 morse taper |

1.7480" 44.399mm |

1.4750" 37.465mm |

5.19" 131.83mm |

| 6 morse taper |

2.4940" 63.348mm |

2.1160" 53.746mm |

7.25"

184.15mm |

| |

|

|

|

To make a quick check to figure out what Morse taper shank

size you have, just measure the large diameter at "A"

and that will more then likely give you enough information

to be able to order the correct shank.

Typical tooling for wood lathes and drill presses in the

woodworking arena are either a MT1 or MT2 so you shouldn't

really have too much trouble identifying which one you have.

There are adapter sleeves that will convert the smaller MT

male taper to hold the larger MT 2 shank, but it is not particularly

advised. Usually if your lathe is designed to use a MT1 taper

it is because it is only structurally designed for smallerl

work. Upping the shank to a MT2 may be dangerous and overload

the capacity of your lathe.

|