Wood Casing: Window Mouldings

Just to confuse, all wood mouldings are given names and the trim that is typically used for window mouldings is referred to as wood casing. Window trim that is used to frame the four sides of a window and hide the seam between the rough drywall edge and jamb (window extension).

The most common species on the market is of course oak casing, at least in my neck of the woods, but it is also commonly available as MDF (raw or prepainted), or Finger-Jointed (FJ) Pine casing. Window mouldings for more exotic treatment can be custom ordered in a long list of wood types as long as you can find a willing manufacturer.

Window mouldings can be installed in a number of different ways. Here's a few ideas.

1.

Traditional Moulding: Window Casing

1.

Traditional Moulding: Window Casing

Each of the four corners around the window are cut (mitered)

at 45°, and the same piece of trim is used on all four

sides. It is typically back set from the jamb 1/8-1/4"

(important not to backset too far or you will have trouble

nailing it into place.

An old time mutation on this is to frame the window as above

and then add a back band to the casing.![]() This

adds a level of sophistication to your trimming efforts and

allows you to high more defects if you scribe it to your drywall's

hills and valleys.

This

adds a level of sophistication to your trimming efforts and

allows you to high more defects if you scribe it to your drywall's

hills and valleys.

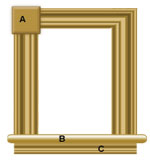

2. Traditional + Corner Blocks

This method of window treatment is similar to the traditional

method,  but

instead of mitering the four corners, square blocks (A) are

used in lieu of the 45° cuts. The corner blocks are typically

aligned perfectly with the inside corners of the window jamb.

The wood casing then is backset from the corner by 1/8-1/4".

The corner block is then between 1/4" - 1/2" wider

then the width of the casing (ie. 3" square corner block

and 2 1/2" wide casing) to allow the wood casing to be

centered on the corner block.

but

instead of mitering the four corners, square blocks (A) are

used in lieu of the 45° cuts. The corner blocks are typically

aligned perfectly with the inside corners of the window jamb.

The wood casing then is backset from the corner by 1/8-1/4".

The corner block is then between 1/4" - 1/2" wider

then the width of the casing (ie. 3" square corner block

and 2 1/2" wide casing) to allow the wood casing to be

centered on the corner block.

#3: Casing a Window Using a Window Sill (B)

Three sides of the window (left, right, top) are framed either

with or without corner blocks using a traditional casing moulding.

Window sills are added to the bottom, typically protruding

from the face of the wall  from

1 1/2"-2 1/2". Often a "skirting moulding"

(C) is added under the sill.

from

1 1/2"-2 1/2". Often a "skirting moulding"

(C) is added under the sill.

#4: Board and Batton:

The left and right legs of the casing are made up of either

straight or fluted boards. A sill ![]() is

added to the bottom typically with another flat board for

the skirting. The header casing is made up of a number of

mouldings (a flat board like the skirting, with a cap on top

and a crown between the two of them, the bottom is often trimmed

with a small beading). It is best to make the header as a

unit before you try and install it over your head.

is

added to the bottom typically with another flat board for

the skirting. The header casing is made up of a number of

mouldings (a flat board like the skirting, with a cap on top

and a crown between the two of them, the bottom is often trimmed

with a small beading). It is best to make the header as a

unit before you try and install it over your head.